Every purchase made online is encrypted with a high level of security you’ve come to expect. Your private information is never shared nor sold, so you can buy with confidence. You can also visit our store if you are in the St. Louis area.

Estimated reading time: 6 minutes

Table of Contents

The Big, Tall, & Not So Small

Why is it mattresses don’t hold up under larger people? Check out our compiled list of the top 10 Reasons mattresses break down or fail.

1. Built For The Average Size:

Usually, the typical mattress is designed and built to support what is often referred to as normal weight and height. While manufacturers consider a variety of firmness they rarely build with real substance mattresses that support people who are medically overweight.

2. Not enough Steel:

Whether it’s due to a lack of good sales training or intentional deception by sales staff, far too much emphasis on coil count and coil design despite advice from websites and consumer advocacy magazines like Consumer Reports have said: “On the whole coil count doesn’t matter”. People who know beds understand one of the most important durability factors is a hefty amount of steel. In other words, it’s about the total amount of steel being utilized. Older styled mattresses utilized big fat springs which weighed more. The coils were bigger and thicker with wire gauge 12 to 12.5 gauge wire. More steel characteristically equals more strength and it was true then and still is the case today.

Related Links

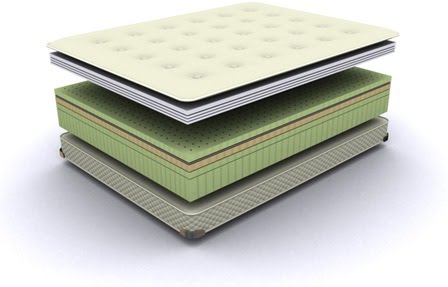

3. Too Much Foam:

Websites like “What’s the Best Mattress” reference “Sleep Like The Dead” for answers concerning the question of failing foam under plus-sized sleepers. They point out that it is especially true in the case of softer, plush, and pillow-top surfaced beds. It is especially interesting that they feel confident in mattresses that range from 10-14 inches in thickness considering how often they have criticized manufacturers for using low-density (poor quality) polyurethane foam which has been notorious for failing prematurely even under average-sized men and women.

4. Box Springs Have Changed:

coil springs that once used to absorb weight and energy have nearly disappeared. There are many reasons for the change. The fact is most are rigid and unforgiving making their slats and framework more susceptible to immediate shock, impact, and weight that can instantaneously cause ridged wire designs to crack, bend, or break foundations. This includes foundations with wooden slats that are spaced too far apart, covered with cardboard, and upholstered with fabric. Good or bad, these bases are no longer built the same and have a tendency to fail quickly.

5. 1 Sided Mattresses:

There are a few one-sided mattresses that can support combined weights of 700 pounds. The majority of them found in your local mattress and furniture store will not withstand this amount of weight. In fact, most of these mattresses are nothing more than overly fluffed upholstery layers of material like foam and fiber that quickly settle and flatten out. Unfortunately, they tend to nest and sag under even the tiniest petite people, which should be of extreme concern for those who consider themselves big and tall or obese or fat. High-quality Latex, dense foam memory foam, and heavy-duty coil springs are the best defense to slow mattress wear.

6. Warranties Are Useless:

Too much weight is given by mattress builders and salespeople concerning the importance of mattress guarantees and consumers often believe that these guarantees have substance and indicate an expected mattress life. The fact is sellers tout them as if they’re something real and special, when the truth is warranted are written by lawyers to favor the bed companies. For example; 10-25 years for something we pay $500.00-$3000.00 The truth is $30,000 cars rarely include more than 5 years of warranty. We need to read and research through third parties to learn what the guarantees cover and if the manufacturers ultimately stand behind consumers’ complaints and issues. Far too often this is a weakness of the industry.

7. Polyester Fiber:

The cushioned upholstery layer makes up the outer fabric cover of the mattress and for years was filled with numerous natural materials. Today the quilted covers that are most vulnerable are overly fluffed and lofted with fiberfill and foam for softness. The resulting problem is that they settle, flatten, and ultimately mat down quickly causing permanent indention. The body impression appears with repeated use of lying in the same place night after night. The surface layer is made up of lofted strands of fiber but can also be made from a mind-boggling variety of natural or synthetic materials. One other important note is that the method of surface quilting, tufting, and hand stitching can also have an effect on how the materials compress and wear under extreme or concentrated body weight. Be sure to research your next mattress quilting process and makeup.

8. Gimmicky Side Reinforcement:

Mattresses are not made to handle the constant load of sitting; they are not a chair. Unfortunately during sale pitches, it often implied that by simply adding a piece of closed cell foam or a row of extra springs it can be used for sitting or as a chair. Most bed sides are not designed or built to hold up under a person of the smallest stature, which is why most of today’s seat edges fail under an immense load of enormous stature. This additional weight transfers pressures down to flimsy foundations that are only built to support the evenly distributed weight of the mattress and average-sized couples.

9. Upholstery Can Buckle:

Migration or shifting of the upholster layers can be a real concern. In many cases, it is made up of glued-together or stitched-together layers that can move and buckle causing bumps or ridges. Extreme pressures can tear or break the sewn-together areas leaving the comfort layers to move around freely causing discomfort or uneven pressure on the sleeper’s body.

10. Not enough insulation:

Some companies have eliminated the old shoddy pad once used to protect upholstery from the cutting edges of wire coil springs. Fiber pads, foam pads, non-woven fabric, netting, or wire mesh insulation is a crucial key protective layer that is placed on top of the coil springs and under the layers of mid-level and surface cushioning. Some insulation materials are better than others but the sole purpose of this insulating layer is to protect the softer layers from being cut into like a cookie cutter. Additionally, it protects layers from being grated up by the edges of the wire coils and settling, dipping, and pocketing into a coil’s large circular openings. The more weight that is pushed down, the greater the damage to the upholstery.

We hope that this article gives you a better understanding of the 10 reasons mattresses break down. If you have any questions or concerns please contact STL Beds below.

Contact STL Beds Now

You can also contact us by filling out the form below. Make sure to fill in as many fields as possible so we can respond to you with the most accurate information!